Steel welded straight & reducing branch pipes

The sphere of usage: for building technological power plants and oil pipelines.

Straight pipes OST 34-10-762-97

The branch pipes, as the name suggests, can be welded of low alloying steel, and carbon steel. They are intended mainly for laying pipelines for thermal power plants. It is worth noting that the products conform to the OST 34-10-762-97 and are fully in line with the working paper 03-94 of a State Committee for Supervision of Industrial and Mining Practices, and should be applied on the pipelines, which fall within the scope of this document. In addition, they can also be used for those pipelines, construction of which is carried out in full accordance to SNIP 3.05.05-84.

The branch pipes, as the name suggests, can be welded of low alloying steel, and carbon steel. They are intended mainly for laying pipelines for thermal power plants. It is worth noting that the products conform to the OST 34-10-762-97 and are fully in line with the working paper 03-94 of a State Committee for Supervision of Industrial and Mining Practices, and should be applied on the pipelines, which fall within the scope of this document. In addition, they can also be used for those pipelines, construction of which is carried out in full accordance to SNIP 3.05.05-84.

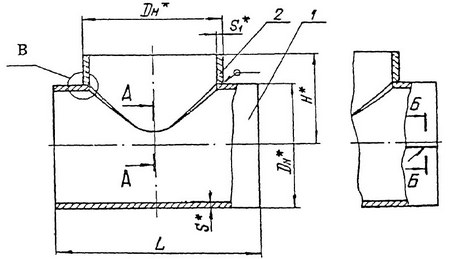

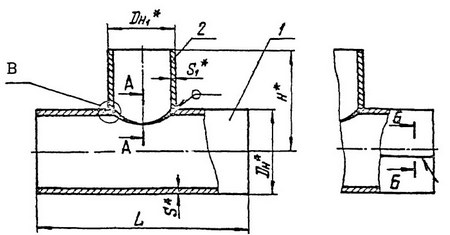

Reducing branch pipes OST 34.10-764-97

RU<= 25MPa (25 kg/sq.cm)

RU<= 25MPa (25 kg/sq.cm)

Reducing pipes constructed in accordance with this standard are welded with a transition method of low-alloyed or carbon steel. They are intended for use on the pipelines, which are laid on thermal power. When the product is supplied with plates, designed for a working pressure of 2.5 MPa. The normal functioning temperature is in most cases up to 200 C.

Welded pipes OST 36-24-77

Du 500-1400 of carbon steel. RU<=25 MPa (25 kg/sq.cm)

The scope of this type of product is primarily technological pipeline element connection of the various directions: petroleum, petrochemical, metallurgical, chemical and etc. Optimally, they should be used on pipes made of carbon steel, specifically in the pipelines, which are laid in accordance with the established rules of State Committee for Supervision of Industrial and Mining Practices. Standard OST 36-24-77 extends to the welded product transition and straight types, made of carbon steel.

Steel branch pipes

Steel branch pipes – are elements with three branches for connecting pipelines construction parts. Such pipes are used for fastening the side branches to the main tube line. When moving through the pipeline a substance reverses its flow at an angle of 90 degrees.

Products have two forms: transitional and straight. There are four ways to produce them:

- Gas cutting metal with subsequent welding;

- Casting into specially prepared forms;

- Hot forging type solid with the subsequent drilling of holes of different diameters;

- Forging from a sheet of rolled products and further machining.

Products are used in systems of hot, cold, heat, chemical, oil and gas industry and in other areas (in accordance with the rules applicable in the Committee for Supervision of Industrial and Mining Practices MTU pipelines 3rd and 4th category). The raw materials for their production are low-alloyed and carbon steel, corrosion and heat resistant steel grade 10Х17Н13М2Т, 15Х5М and 12X18H10T.

Depending on the production method, such pipes can be divided into welded, seamless, welded-forged and chiseled. Straight pipes are distinguished from transient so that their outlets have identical diameters, while straight pipes’ diameters of different outlets are different.