Hanger springs for pipelines of CHP and Atomic Power stations according to OST 108.764.01-80

Leningrad metal plant Co., Ltd. in addition to complete pipeline systems, also supplies parts and spares for utilities and pipelines, which can be used in industry, for example, in the chemical, oil and gas and petrochemical industries.

Hanger springs OST 108.764.01-80 that we produce, are needed to address the oscillatory movements in oil pipelines, gas pipelines, water pipes and boiler equipment. In addition to the standard, we are able to manufacture springs according to custom drawings.

Hanger springs OST 108.764.01-80 that we produce, are needed to address the oscillatory movements in oil pipelines, gas pipelines, water pipes and boiler equipment. In addition to the standard, we are able to manufacture springs according to custom drawings.

Suspension of the pipeline is a steel structure, which consists of a number of series-connected parts. Suspension may consist of one chain or multiple. Chain takes the weight of the pipe by passing it to the building structure. In the manufacture of trimmings do not use welding, but only the mechanical method.

Given the design of circuits and components to the pipeline, suspensions can be divided into several types. The sites are divided into 7 species. The most common hard and spring, designed to fit in a horizontal or vertical pipelines. The diameter varies from 25 to 1400 mm.

Hanger springs for thermal and nuclear power plants pipelines

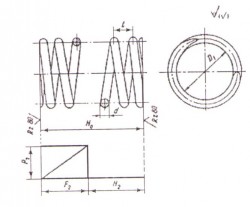

Products of this type are equipped with screw-type coil springs compress. They are manufactured in strict accordance with the requirements of OST 108.764.01-80. It also must conform to the structure, strength, and size details.

Those products, which consist of six or less turns, usually have a margin of ± 0.25 of evolution, and the accuracy of parts with twelve revolutions can be up to ± 0.5 of the evolution.

In the manufacture of steel structures we use hot brandy. These are hot-rolled products with the leg surface. This allows us to prevent the decarburization of steel. We produce carbon and alloy spring steel. In order to make the surface more resistant to aggressive environmental influences, we process the anticorrosive materials: varnish, primer, paint or polymer-powder coating.

Over the years we have worked closely with both Russian industrial enterprises and large enterprises of CIS countries and far abroad. This attests to the excellent reputation of our factory and is a guarantee of excellent quality.

Technical characteristics

The standard establishes the design, dimensions and technical specifications of the suspension springs on the EAST with the force of 1, 26kN (128kgs) to 58, 45kN (5960) when working 70 and 140 mm deformations, designed for work at temperature from-40 to + 120° C.

| Position | d, mm | Weight, kg | Flat pattern, m |

| 1 | 10 | 1,4 | 2,31 |

| 2 | 12 | 1,9 | 2,18 |

| 3 | 16 | 3,8 | 2,48 |

| 4 | 18 | 4,9 | 3,6 |

| 5 | 20 | 6,2 | 2,55 |

| 6 | 22 | 7,6 | 2,59 |

| 7 | 24 | 9,9 | 2,85 |

| 8 | 28 | 13,8 | 2,92 |

| 9 | 32 | 21,8 | 3,54 |

| 10 | 34 | 24,9 | 3,58 |

| 11 | 36 | 28,2 | 3,62 |

| 12 | 40 | 34,7 | 3,61 |

| 13 | 10 | 2,4 | 3,96 |

| 14 | 12 | 3,2 | 3,7 |

| 15 | 16 | 6,4 | 4,13 |

| 16 | 18 | 8,2 | 4,19 |

| 17 | 20 | 10,2 | 4,26 |

| 18 | 22 | 12,6 | 4,32 |

| 19 | 24 | 16,7 | 4,82 |

| 20 | 28 | 22,5 | 4,78 |

| 21 | 32 | 36,9 | 5,98 |

| 22 | 34 | 42,1 | 6,05 |

| 23 | 36 | 47,8 | 6,12 |

| 24 | 40 | 56,8 | 5,9 |

Additional information

- The design, size and strength of hanger springs must correspond to the indications given in the OST 108.764.01-80. They shall be made in accordance with the requirements of this standard.

- Material - round hot rolled steel with precision rolling mill Group B according GOST 2590-71 with the technical requirements of the requirements according to GOST 14959-69 for spring steel grade 60S2; grade 60S2A.

- Coiling is not installed.

- For products, coiled hot tolerance of the boom ends.

- For springs with the number of active coils up to 6 (working strain F2 = 70 mm) deviation evolutions from the nominal value shall be within ± 0.25 of the revolution, and for springs with the number of active coils up to 12 inclusive (working strain F2 = I40 mm) ± 0.5 of the evolution.